INTRODUCTION

The past 3 years of experience in our practice have made it clear that 3D printing provides numerous benefits for both patients and practices. The process of taking digital impressions is much more comfortable for the patient than the conventional process of using alginate and pouring into stone. The 3D printing process eliminates the bubbles and imperfections that often result from the conventional manufacturing approach, while offering much better precision and durability. In-office 3D printing also reduces the number of office visits — which is especially important for patients who live far from the office. If a printed device is ever lost or damaged, a replacement can quickly be printed using the existing model. In addition, the use of a digital workflow makes it easier for patients to visualize how their teeth will look in the provisional stage, reducing the number of adjustments and laboratory reconstructions in the final stage. Finally, patients benefit from same-day 3D printing of retainers, which avoids the risk of recurrence that could occur if the patient does not show up for a follow-up appointment to receive a laboratory retainer.

Our practice also enjoys many benefits from 3D printing, including streamlining workflow, significantly reducing lab work and reprocessing costs, reducing shipping costs, and providing a more predictable result with greater control.

The benefits of 3D printing are especially important when patients need orthodontic treatment followed by restorative treatment, as shown in the following 2 cases.

CASE REPORTS

Case 1

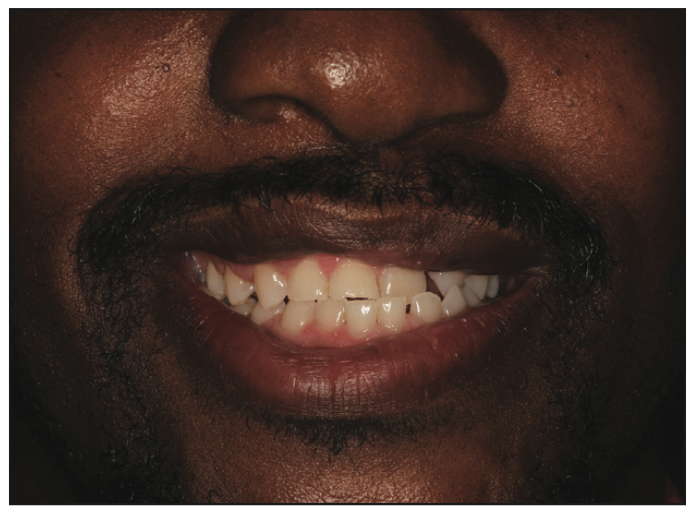

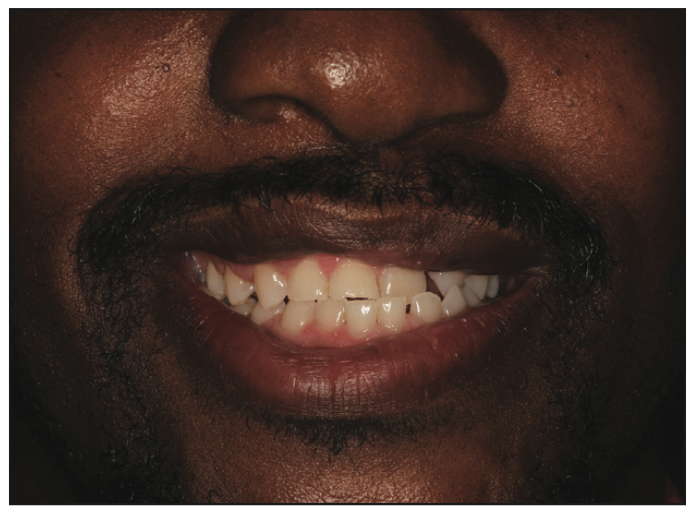

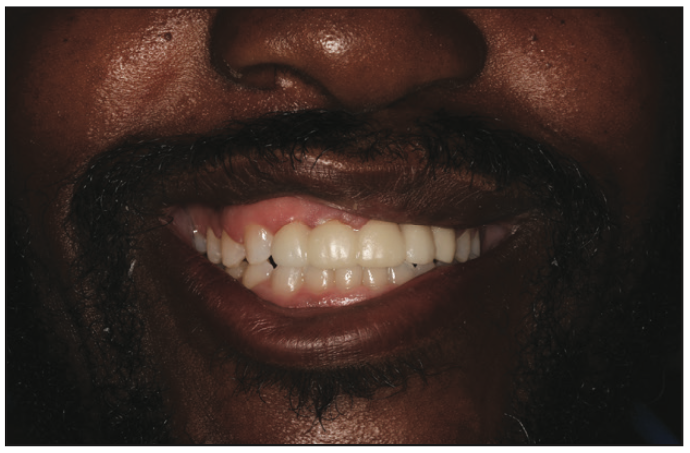

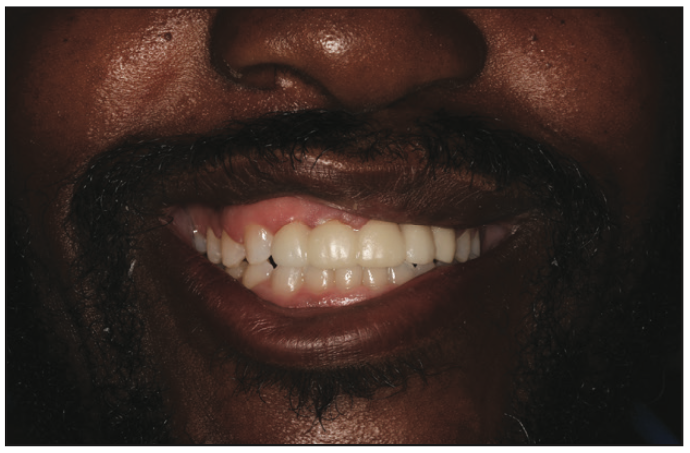

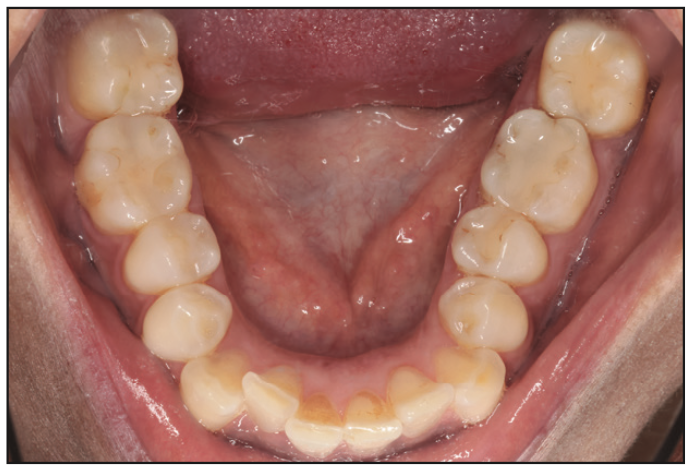

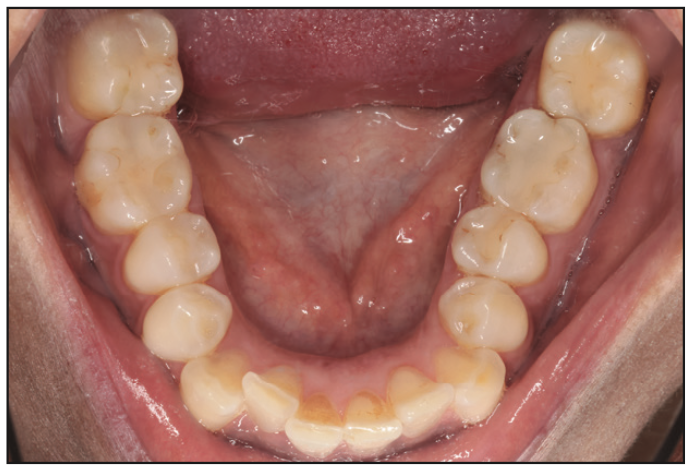

A 46-year-old male patient presented with a medical history that included cleft lip and palate repair and was also missing an upper left lateral segment (Figure 1). His upper midline had shifted to the left of his facial midline due to the asymmetry (Figure 2). Only 3 mm of space was available between the upper left canine and the central incisor to replace tooth No. 10. There was an anterior intersection of Nos. 9 and No. 11 with Nos. 22 to 24 (Figure 3), causing fremitus and a horizontal fracture line in No. 9. In addition, No. 8 was in end-to-end occlusion with Nos. 25 and 26, leading to excessive incisal wear on No. 8 as well as No. 7 (Figure 4) . The patient wished not only to improve the aesthetics of his smile but also to deal with the trauma caused by the abnormality.

Figure 1. The original image of the upper arch shows tooth #10 missing.

Figure 2. Initial low smile view showing the upper midline to the left of the facial midline.

Figure 3. Original intraoral image showing missing No. 10 and intersection of Nos. 9 and 11 with Nos. 22 to 24.

Figure 4. Initial end-to-end intraoral view between No. 8 and Nos. 25 and 26.

Figure 5. Post-ortho intraoral view showing space created for Nos. 7, 8 and 10 and the corrected crossbite.

In order to restore the patient’s dentition, orthodontics was necessary and the patient preferred clear aligner treatment. Invisalign aligners were used to create 7 mm of space to replace No. 10 (Figure 5), to insert Nos. 7 and 8 for sufficient clearance for future crowns, to close the bottom gap, and to correct of the crossbite. Implant was not an option due to insufficient amount of available bone. Instead, we decided to place crowns on Nos. 7 and 8 and a bridge on Nos. 9 to 11. The orthodontic treatment lasted 17 months and included 2 enhancements. During Invisalign (Align Technology) treatment, shade A1 pontic color was placed on the number 10 pontic in the aligner, so it was not obvious that the patient was missing a tooth. This is a major advantage of using clear aligners when a patient is missing a front tooth and why Invisalign is preferred in these cases (Figure 6).

Figure 6. Metarectal maxillary arch.

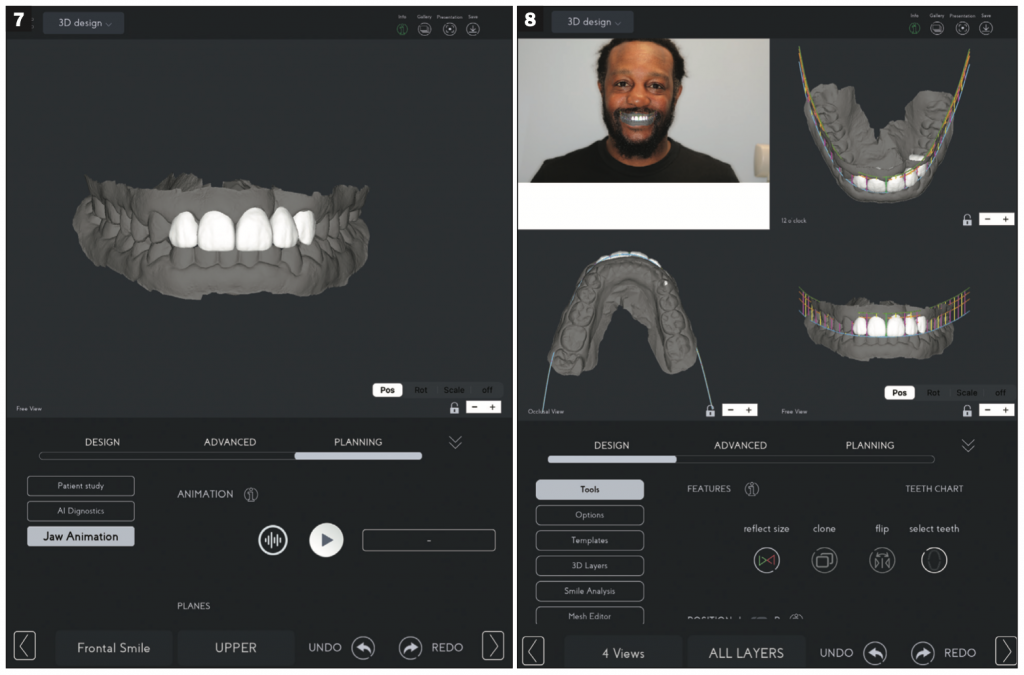

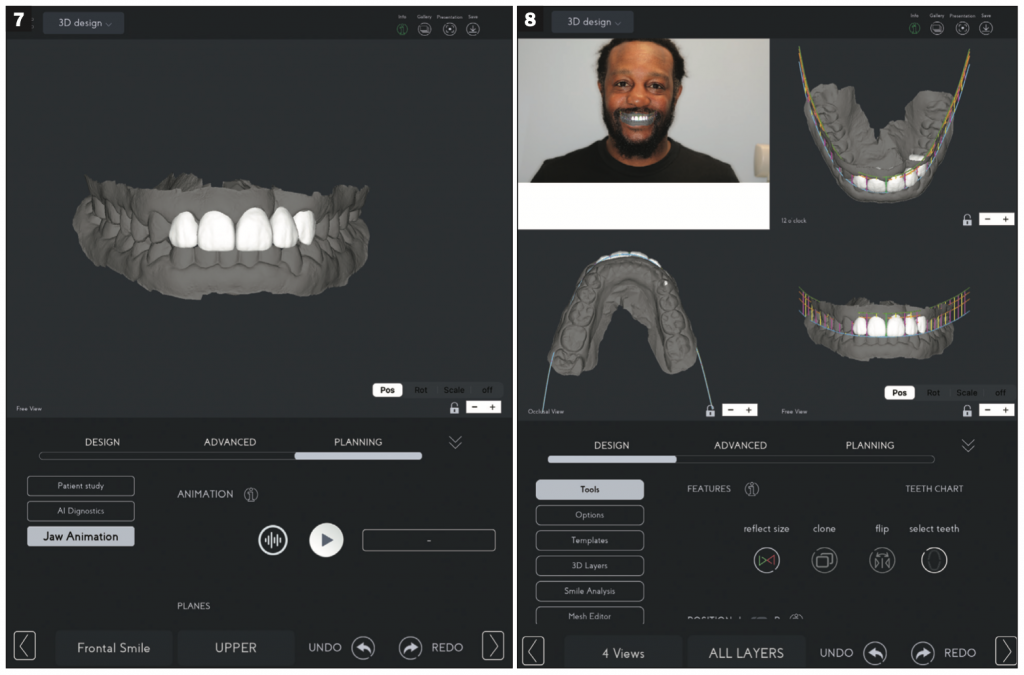

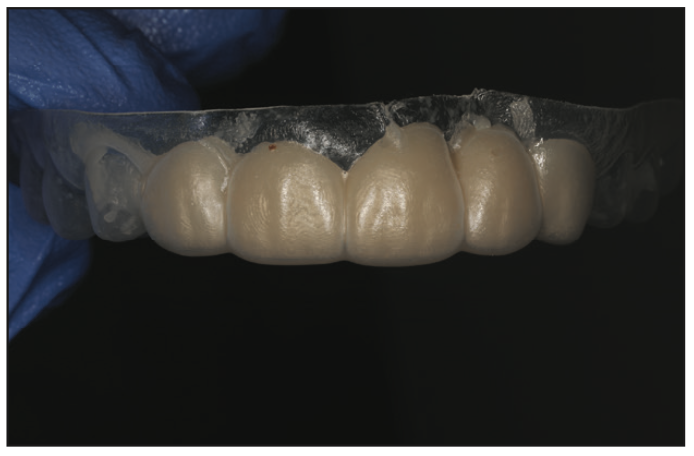

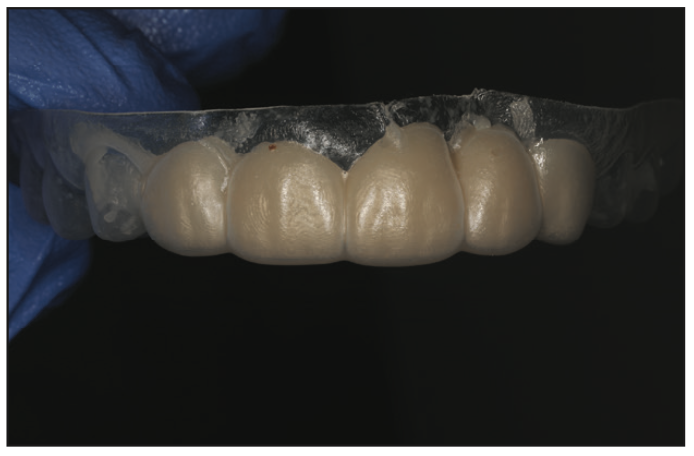

Once the orthodontic treatment was completed, the attachments were removed and using a digital scanner (iTero Element 5D [Align Technology]), STL files of the final occlusion were created and temporary retainers were printed at the desk on the 3D printer (3Demax [DMG]) using 3D printing resin (LuxaPrint Model [DMG]). The STL files were uploaded to the design software (3D AI Mockup Design [SmileFy]), which was used to design teeth Nos. 7 to 11 (Figures 7 and 8). The STL files were then imported into nesting and cutting software (Netfabb [Autodesk]) and a model of the patient’s upper arch with the 3D designed anterior teeth was printed using the LuxaPrint model. A positive pressure machine was used to construct the stent for the temporary crowns in Nos. 7 and 8 as well as a temporary bridge for Nos. 9 to 11 (Figures 9 and 10). The model was passed through the curing unit (3Decure [DMG]) and washing unit (3Dewash [DMG]).

Figures 7 and 8. Crown and bridge designed using SmileFy software.

Figure 9. Stent.

Figure 10. Stent.

Figure 11. Teeth prepared for restorative treatment.

For temporary crowns and bridge, a high-performance crown and bridge material (LuxaCrown [DMG]) was used. After preparing the teeth (Figure 11), they were provisionally placed (Figure 12) using an esthetically oriented temporary cement (TempoCem ID [DMG]). I use it for all my temporaries because of its incredible ability to allow the temporary to stay on but leave no residue on the tooth when removed. From the design model, printed earlier, a retainer was printed to protect the temporaries and prevent the teeth from shifting before the final restoration.

Figure 12. Patient with temporary structures with LuxaCrown (DMG) and cemented with TempoCem ID (DMG).

Figure 13. Final intraoral image.

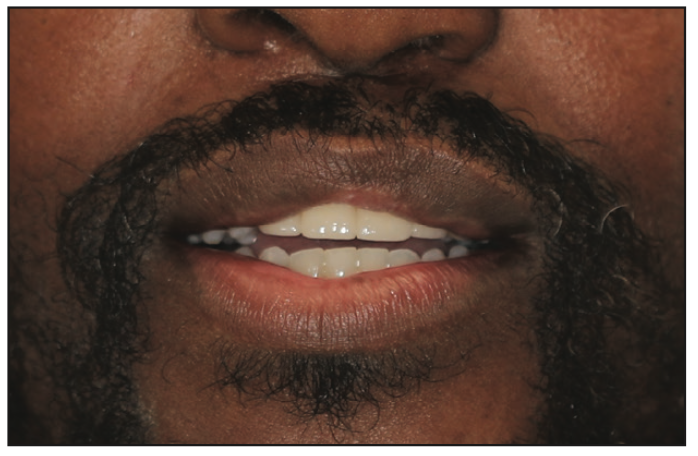

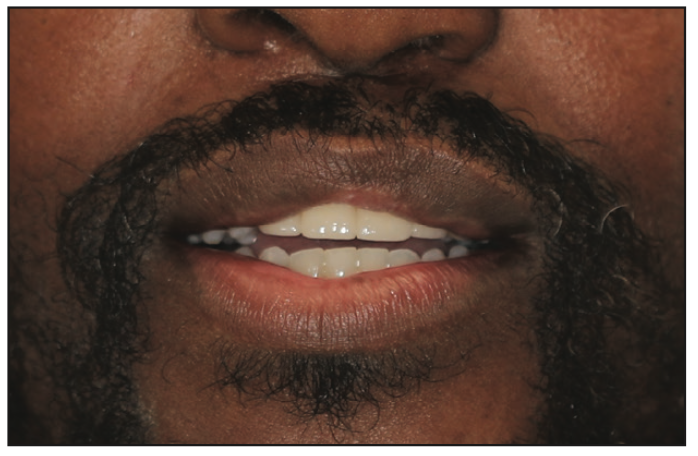

Figure 14. Patient with final restoration.

The final design of the temporary was sent to the outside lab to give the lab a clear idea of what the permanent restoration should look like. Permanent restorations were fabricated using KATANA multilayer zirconia [Kuraray Noritake]). Once the final restoration was cemented (Figure 13), we took a scan right after and printed a model for a permanent retainer the same day. The patient was extremely pleased with the result (Figure 14).

Case 2

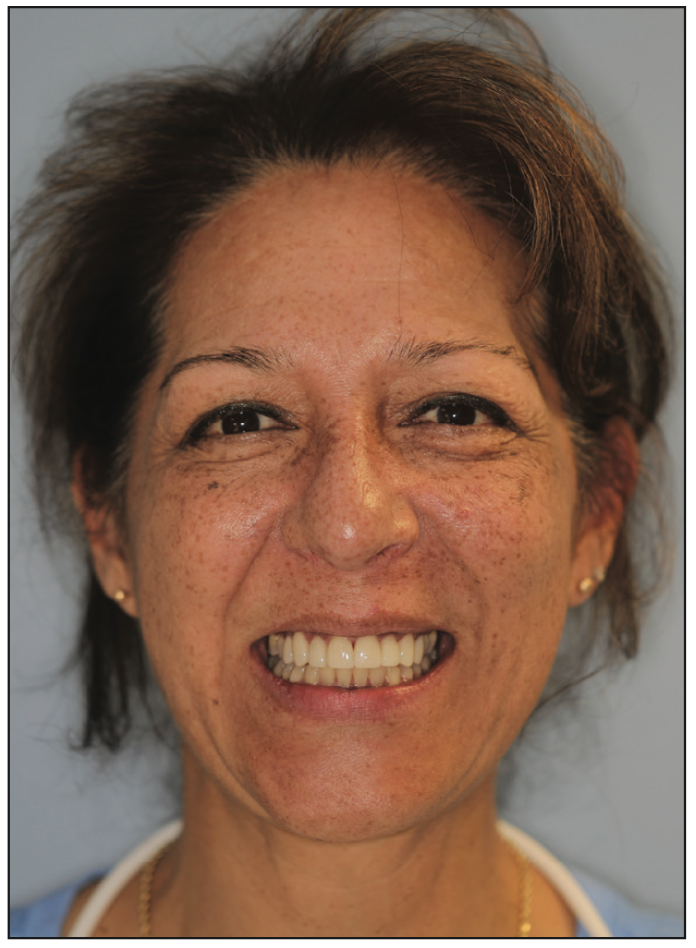

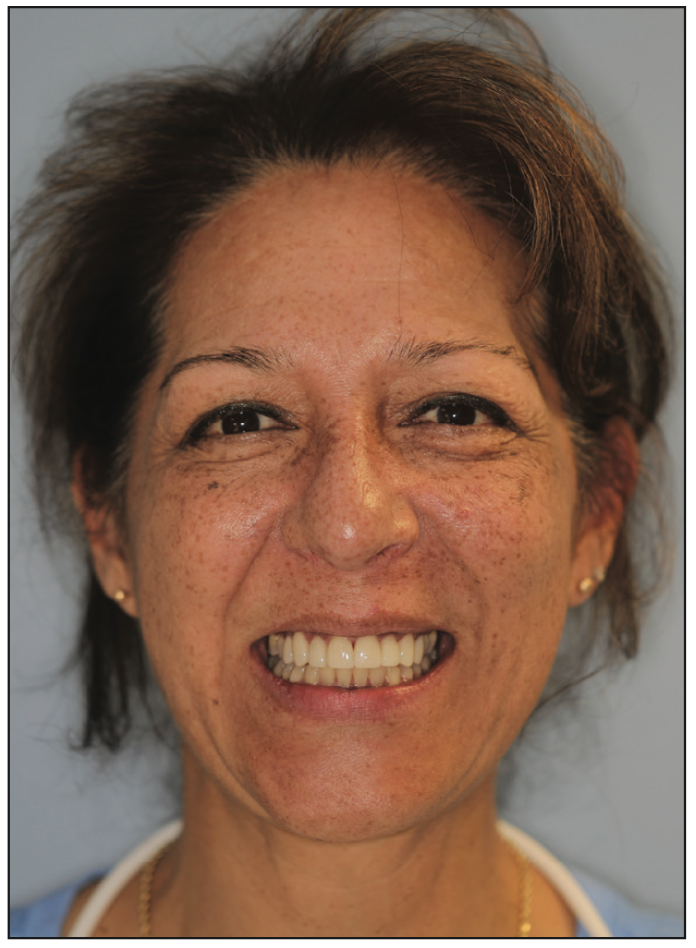

A 50-year-old woman presented who was not satisfied with the esthetics of her veneers that had been placed more than 20 years ago (Figure 15). She showed significant recession around the veneers and significant staining at the veneer margins and composite material placed over the tooth roots (Figure 16). In order to achieve the wide smile he desired, orthodontic treatment was necessary. This was done to correct the unilateral functional posterior crossing caused by the narrow palate and rightward displacement of the mandible when she closed her mouth. We also needed to correct the upper midline, which had a significant slope to its left (Figure 17).

Figure 15. Patient with features of 20 years and older.

Figure 16. Staining visible in the margins and complex accumulations and in the posterior crossbite.

Figure 17. The patient’s upper midline tilt to the left is evident.

In this case, the patient preferred fixed devices to removable ones. Props (Damon System [Ormco]) were designed using orthodontic planning software (Insignia Advantage [Ormco]). The width of the maxillary arch was increased by straightening the lingually inclined posterior teeth, and the crossbite was corrected with an elastic cross on the right side. Orthodontic treatment lasted 14 months (Figures 18 to 22).

Figure 18. Pre-rectal view of the mandible.

Figure 19. Pre-rectal view of the maxilla.

Figure 20. Post-rectal view of the mandible.

Figure 21. Post-rectal view of the maxilla.

Figure 22. Post-rectal view of the patient’s smile.

When her orthodontic treatment was completed, her teeth were scanned using the iTero Element 5D, brackets were digitally removed from the STL file using triangle mesh software (Meshmixer [Autodesk]), and the 3Demax printer was used to create top and bottom retainers. Creating retainers early was beneficial as, at the arm removal appointment, her retainers were able to be delivered immediately.

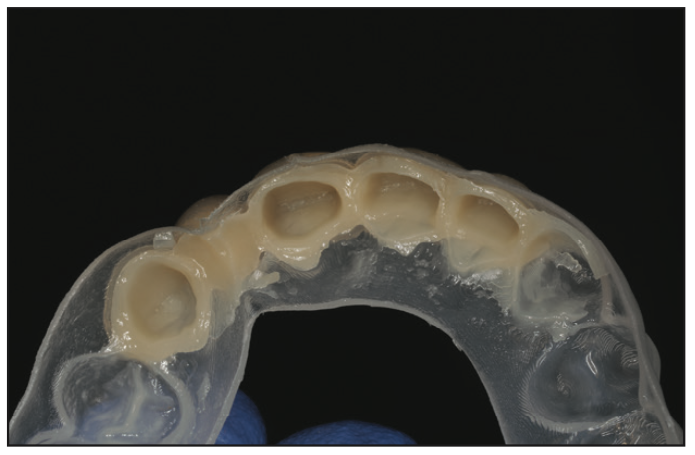

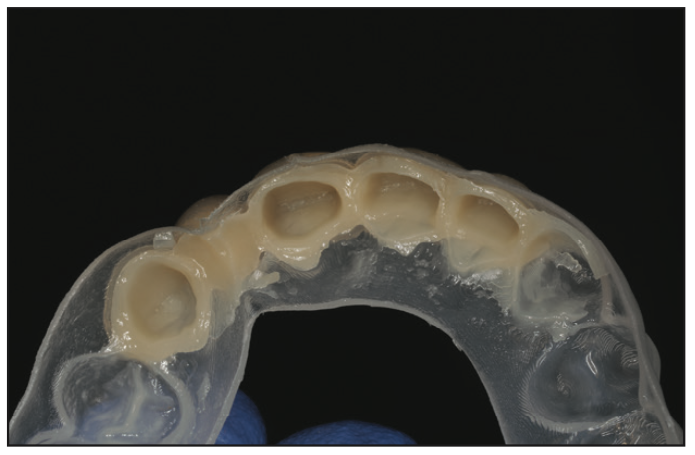

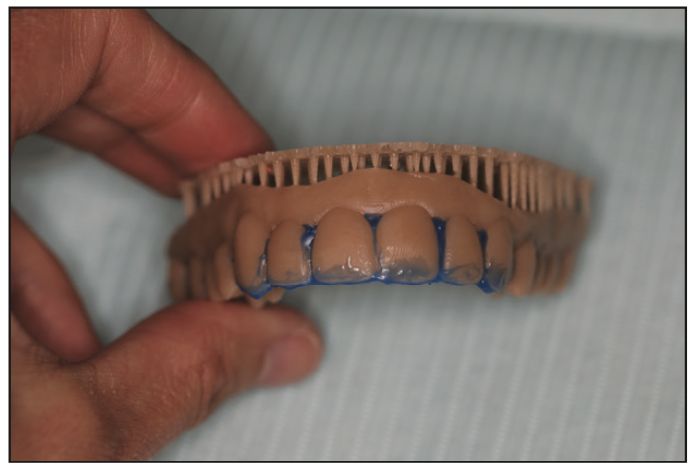

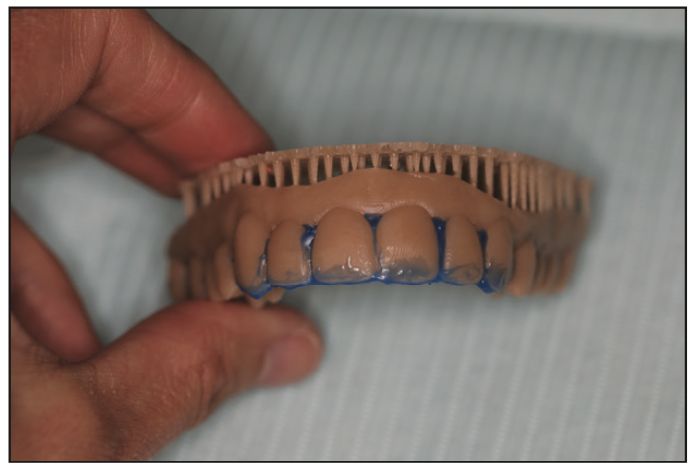

To plan her restorations, the same STL file was imported into SmifeFy design software, which was used to design 8 provisionals from first premolar to first premolar. The model was printed (Figure 23) using LuxaPrint Model 3D printing resin and a positive pressure machine was used to create the stent and retainer (Figure 24). After removing the old veneers and preparing the teeth for new restorations, the stent was used to construct the temporary veneers (Figure 25) with a temporary crown and bridge material (Luxatemp [DMG]). These were cemented using an invisible temporary cement (TempoCem ID [DMG]).

Figure 23. The 3D printed block model for the fabrication of retainers.

Figure 24. The 3D printed stent from the designed STL file.

Figure 25. The patient with cemented temporary veneers.

Figure 26. The patient with cemented permanent veneers.

While I was very pleased with the appearance and fit of the temporaries, the patient was used to her teeth being shorter and requested that her upper front teeth be slightly shortened. Her request was easy to accommodate as the design file was simply sent to the outside lab and they were instructed to shorten the upper anterior teeth by 1mm. The final veneers were fabricated using lithium bisilicate glass ceramic (IPS e.max [Ivoclar]). They were cemented using PANAVIA Veneer LC (Kuraray Noritake). The patient was very pleased with the final result (Figure 26).

CONCLUSION

Our 16-room practice does a lot of orthodontic work, often followed by restorative work, as in the 2 cases above, and using 3D printing in this work has been a real game changer for our patients and us.

ABOUT THE AUTHOR

Dr. Latham she received a BS from Boston University, where she was valedictorian, and a DDS from the University of Michigan School of Dentistry. He is currently a general dentist in a 4 doctor, 16 operating room practice in Stratford, Conn. He previously served in a military dental clinic in Rota, Spain and in private practice in Virginia Beach, Va. He has completed several postdoctoral courses in Orthodontics and Invisalign. Dr. Latham is a recipient of the William S. Kramer Award of Excellence from Omicron Kappa Upsilon, a member of the International Association of Orthodontists and a Platinum Invisalign provider. She grew up in New Zealand and moved to the Pacific in 2001 to attend Boston University and compete as a track and field athlete. She can be reached at julialathamdds@gmail.com.

Disclosure: Dr. Latham reports no disclosures.